GIFLOR ENHANCES DISPENSING PERFORMANCE WITH A NEW VERSION OF 730 CLOSURE

Published 9 November 2022

Dispensing performance is undoubtedly the most important element in assessing the functionality and effectiveness of a closure system. A cap that prevents the product from flowing out correctly, with too little or too much dosage, can make the user experience frustrating and lead consumers to change their purchasing choices (at least next time…).

But how can you avoid these unpleasant inconveniences and ensure perfect dispensing in every situation?

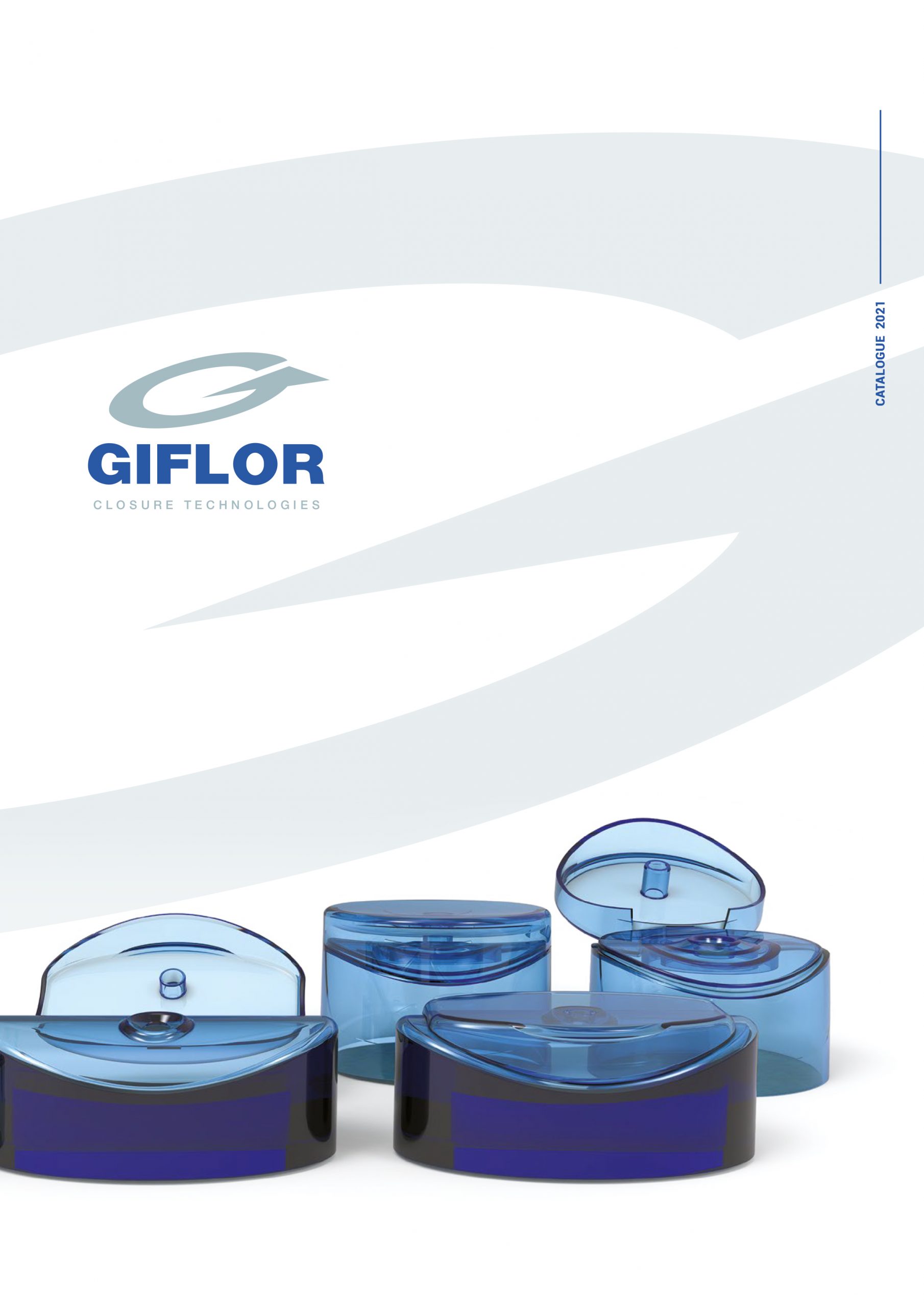

For Giflor Closure Technologies, the answer is to design the closure according to the formulation and the specific density and flow characteristics of the products to which the cap will be applied. Starting from this concept, in the last year Giflor’s R&D team has been working on the development of one of the flagship items of the Classic Line collection, the round flip-top cap art. 730, which is now ready to be launched on the market in a new version without valve.

This evolution of art. 730 has been specially conceived for powders, highly viscous liquids and microgranular products that are now widely used in various markets, such as cosmetics, personal care and food, for products that go from creamy salad dressing, to washing machine powders and solid shampoo.

Made of PP Copo, the 730 cap offers exceptional dispensing performance for this type of materials thanks to its large 10 mm orifice. The screw-on coupling combined with the crab claw sealing system increases the feeling of control and security for the end user, while the matte finish adds to the pleasure of the tactile experience. Also, in its new valve-less version, the 730 cap is available in over 350 standard colors.

Download the 2024 Product Map

Discover all the solutions available to you by consulting the latest edition of our Product Map.

DOWNLOAD PDF

Request Catalogue

Contacts

One of our consultants is at your disposal to satisfy your requests and offer you all the necessary assistance

CONTACT US