Industrial plant, materials, design: Giflor is three times green

Published 23 June 2022

How many ways are there to be eco-responsible? More than 15 years ago, Giflor Closure Technologies took up the challenge of sustainability knowing that a single product or innovation would have not been enough to make a difference for the environment. To bring about a real change, you need to have a broader perspective, a vision that involves the whole industrial process, from design to production.

In 2006, Giflor produced the first two caps with a reduced size that started the Eco Low Profile line, art. 741 and art. 742, made with an ultralight design and 50% less plastic. Since that first steps, numerous innovations and investments targeting sustainability followed. Year after year, achievement after achievement, today we can say that Giflor is three times green, three times committed to the environment.

First green asset: sustainable industrial plant.

Always on the lookout for the latest technologies and procedures that can help lowering its environmental footprint, Giflor equipped its production facility with hybrid and full electric injection-molding machines capable of significantly reducing energy consumption and harmful emissions. To make the process even more efficient and sustainable, Giflor has also adopted an innovative water-saving cooling system – that increases temperature stability within the plant and allows to save up to 90% of water, as well as LED lights in the whole industrial plant.

Second green asset: sustainable materials.

Giflor has been an absolute pioneer in the use of in the use of recyclable, recycled and bio-based plastics. The outcome of the R&D department’s efforts in this area is that all Giflor’s caps today are monomaterial and recyclable. In addition to that, most of products are available in recycled resins such as PCR (Post Consumer Resin), and in HDPE (High Density Poly Ethylene). Another significant innovation is the development of Carbon Black Free resin, which ensures the proper identification and disposal of black plastic closures in the recycling value chain.

Third green asset: sustainable packaging design.

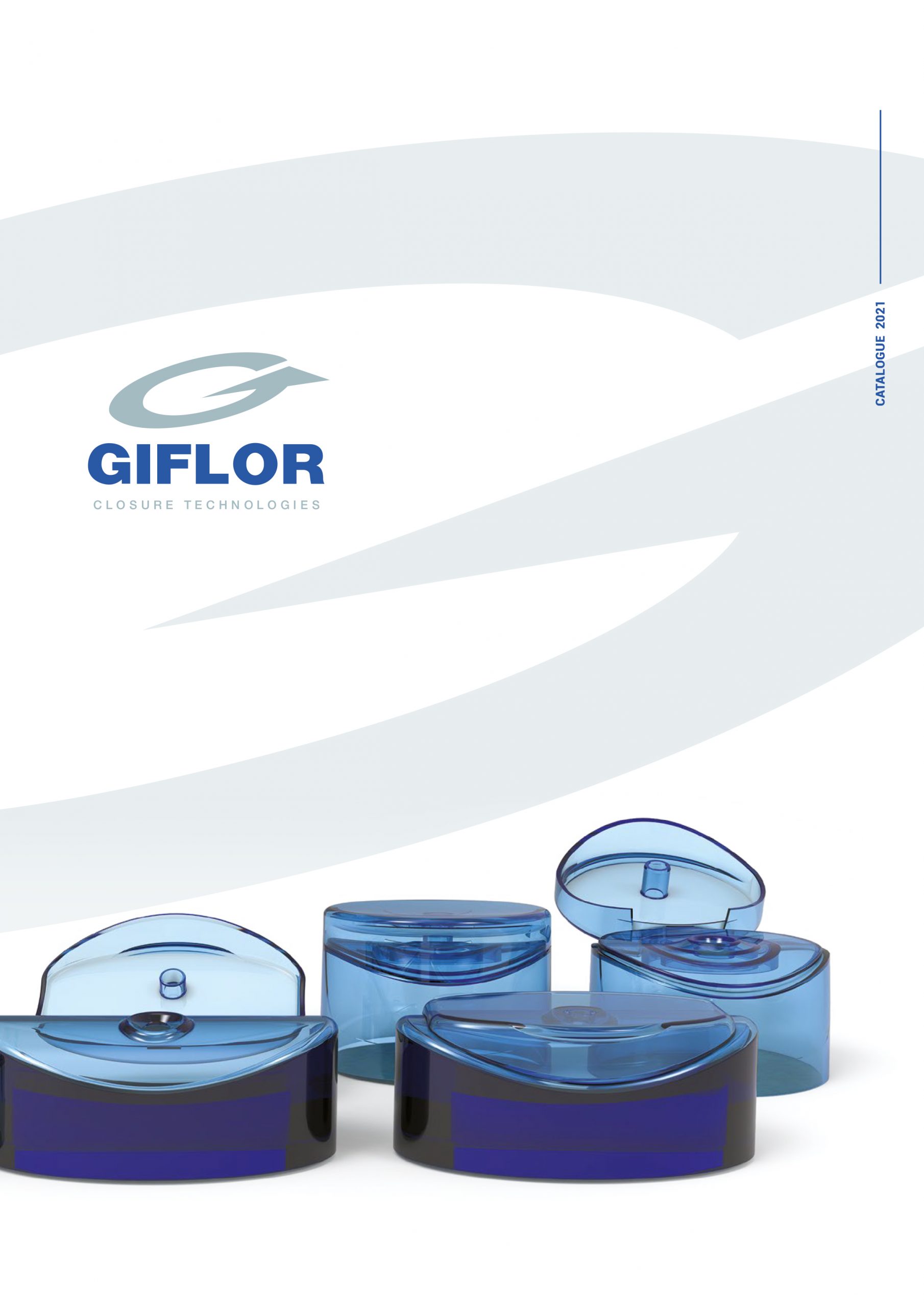

Giflor’s R&D department is constantly raising the bar to create closure systems that are original, functional, beautiful and sustainable. Eco Low Profile caps were designed to minimize the environmental impact, during the production process, in the final product and within the related supply chain. Over the years, this collection has been expanded and perfected, also coming to cover new areas of application, such as tubes. Giflor developed ELP closures for tubes of different dimensions, as well as a 100% recyclable monomaterial tube system (awarded by the Tube Council in 2020 and 2021) in collaboration with international partners.

Download the 2024 Product Map

Discover all the solutions available to you by consulting the latest edition of our Product Map.

DOWNLOAD PDF

Request Catalogue

Contacts

One of our consultants is at your disposal to satisfy your requests and offer you all the necessary assistance

CONTACT US